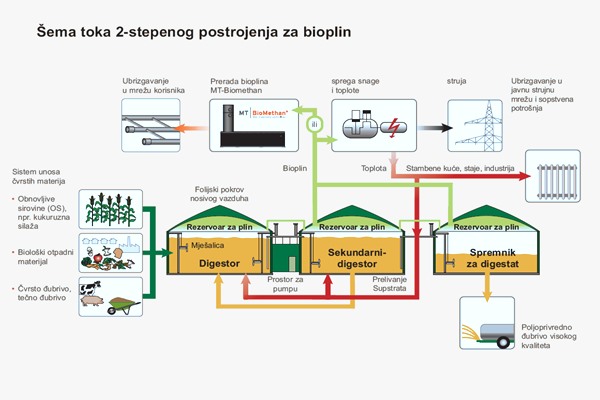

The fermentation process in a biogas plant takes place in an anaerobic, thermally insulated and heated tank, called digester. Digesters are regularly fed with fresh biomass. The bacteria in the digester transform the biomass into biogas and digestate. The energy value of the produced biogas is from 5.2 to 6.5 kWh / m3 of biogas. 83.8% of the generated energy is produced in the process of co-production or cogeneration, and the rest comes from conversion. This energy produces about 42.1% of electricity and 41.7% of heat.

Electricity is distributed to the grid according to the “green” tariff, and heat is partially (up to 30%) used to heat the substrate at the entrance to the fermenter. The rest of the heat is used to produce a coolant and is used for the company’s own needs.

Materials suitable for biogas production include:

- manure and field biomass from agriculture;

- crop by-products (straw, silage, pulp);

- bird droppings, dung of pigs and cattle;

- organic part of municipal solid waste;

- catering waste.

To obtain a stable and efficient biogas production, there are several conditions to be taken into:

- being located close to the suppliers of raw materials;

- integrated use of biogas plant products.

The close location of biogas plant “Bioplinara Organika Kalnik 1” to agricultural complexes contributes to the effective and efficient growth of biogas deployment.

About 35 thousand tons of corn silage are purchased annually, which contributes to the development and employment of more than 100 farms.

As the Integrated Pollution Prevention and Control Directive of the European Parliament and of the Council restricts the ability of farmers to export substrates directly to the fields, 60 tons of such raw materials are transported daily by neighboring farmers to the station in exchange for processed digestate, which is a first-class organic fertilizer.

The use of the biofertilizers enhance soil texture by increasing amount of humus and maintain soil fertility.

Eco-friendly in nature and pollution free.

Since 2018, Bioplinara organica Kalnik 1 annually receives tens of thousands of tons of biowaste from industrial enterprises, the food industry, and waste from the restaurant and hotel business.

In 2019, a contract was signed with the city of Zagreb, Republic of Croatia, for the reception and processing of sorted biowaste into. This contributes to the implementation of the ecological concept of waste-free production and increases the income in the economic balance of the biogas plant.

The main production process of the biogas plant is mesophilic anaerobic fermentation. This process involves the biological decomposition of organic raw materials at a temperature of about 40 ° C in sealed fermentors without the participation of oxygen with the help of bacteria with the release of biogas, which consists of more than half of methane.

Biogas is used as a fuel in highly efficient cogeneration plants that simultaneously generate electricity and heat.

The generated electricity is supplied to the Croatian power grid at a subsidized guaranteed tariff on the basis of a long-term contract with the national Croatian operator HROTE, which is the main income item of the biogas plant, and is also used for its own technological needs.

Thermal energy is used to maintain a stable process temperature in fermentors, and is also used to supply heat to an office center owned by the BIOEN Group of Companies.